Selecting the right fasteners is critical for any construction, machinery, or industrial project. High-quality stainless steel fasteners are essential in ensuring the safety, durability, and longevity of assemblies, especially in corrosive environments. But how can you distinguish top-grade stainless steel nuts and bolts from substandard ones? Here’s a comprehensive guide.

1. Material and Corrosion Resistance

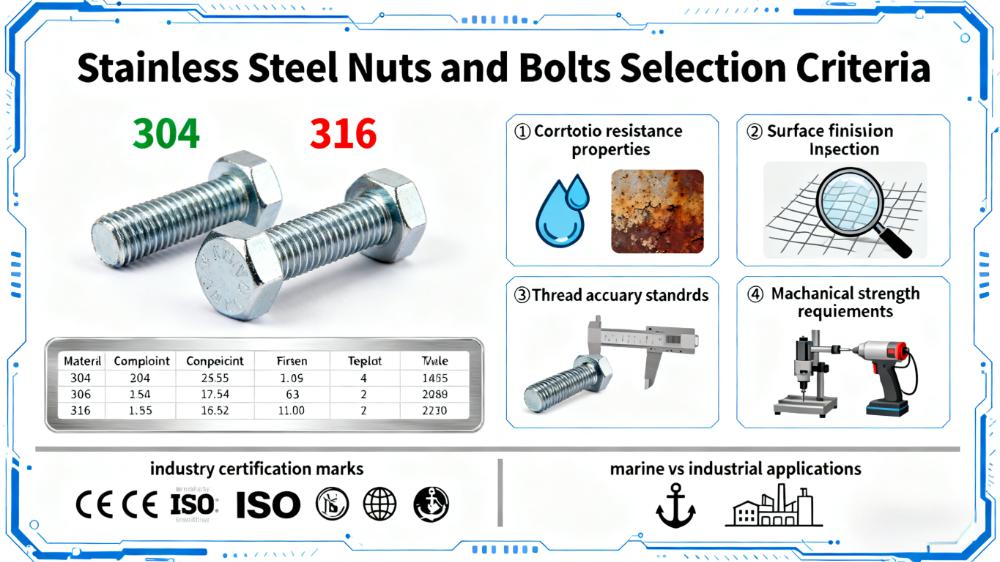

The first factor to consider when choosing stainless steel nuts and bolts is their corrosion resistance. High-quality stainless steel is designed to withstand rust, oxidation, and chemical exposure, making it suitable for outdoor, marine, or industrial applications. Check the material grade — commonly used grades like 304 and 316 stainless steel provide excellent corrosion resistance and durability.

2. Surface Finish and Manufacturing

Top-tier stainless steel bolts and nuts have a smooth and consistent surface finish. The presence of burrs, scratches, or discoloration may indicate poor machining or inferior materials. High-quality fasteners including bolts and nuts should be well-polished and free of surface defects, ensuring not only aesthetics but also functional reliability.

3. Strength and Mechanical Properties

The mechanical performance of stainless steel fasteners is just as important as their corrosion resistance. Quality stainless steel bolts should have high tensile strength and be able to handle the mechanical loads specified for their application. Check for certification marks or grade stamps on the fasteners, which indicate compliance with industry standards.

4. Thread Accuracy

Accurate threading ensures secure fastening and prevents loosening over time. High-quality stainless steel fasteners are precision-threaded, allowing easy assembly while maintaining a tight grip. Inferior threading can compromise the integrity of the joint and reduce the overall lifespan of the assembly.

5. Supplier Reputation

Sourcing from a reputable manufacturer or supplier is critical. Reliable suppliers provide quality assurance, material certifications, and often test their products to meet international standards. This guarantees that the fasteners including stainless steel nuts and bolts you purchase will perform as expected, even in corrosive environments.

6. Price vs. Quality

While low-cost fasteners may seem attractive, they often compromise on material quality and performance. Investing in high-quality stainless steel fasteners ensures long-term reliability, reduces maintenance costs, and prevents potential safety issues.

FAQs About Stainless Steel Nuts and Bolts

Q1: How can I tell if stainless steel fasteners are corrosion-resistant?

A1: Check the material grade (e.g., 304 or 316 stainless steel) and ensure the fasteners have a smooth, defect-free surface. Proper certification from the supplier also indicates strong corrosion resistance.

Q2: Are all stainless steel bolts suitable for corrosive environments?

A2: Not all. High-grade stainless steel, particularly 316, is best suited for harsh or corrosive environments due to its superior resistance to rust and chemical exposure.

Q3: Why is thread accuracy important in stainless steel fasteners?

A3: Accurate threading ensures secure fastening, prevents loosening over time, and maintains the integrity of the assembly.

Q4: Can I rely solely on price to determine quality?

A4: No. Low-cost fasteners may compromise on material and performance. Quality should be verified through supplier reputation, certifications, and material grade.

Q5: What are key signs of high-quality stainless steel nuts and bolts?

A5: Excellent corrosion resistance, smooth surface finish, precise threading, mechanical strength, and sourcing from reputable suppliers.