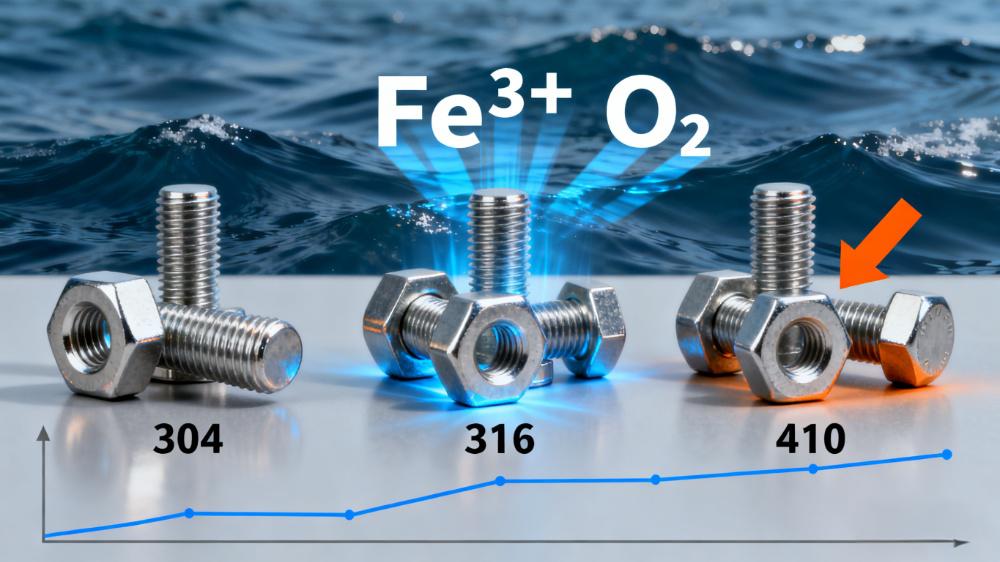

When selecting stainless steel fasteners, one of the most important considerations is their corrosion resistance. Different grades of stainless steel perform differently in various corrosive environments, and understanding these differences helps ensure long-lasting performance and safety in your applications.

Understanding Corrosion Resistance in Stainless Steel Fasteners

Stainless steel fasteners are widely used across industries because of their ability to resist rust, oxidation, and chemical damage. The main reason behind their corrosion resistant properties lies in the presence of chromium — a key alloying element that forms a thin, protective oxide layer on the steel’s surface.

However, not all stainless steel grades are created equal. The composition of elements such as nickel, molybdenum, and chromium varies among grades, directly impacting their performance against corrosion.

Common Stainless Steel Grades and Their Corrosion Resistance

1. 304 Stainless Steel Fasteners

304 stainless steel is the most commonly used grade for general-purpose applications. It offers good corrosion resistance in mild environments, such as indoor settings or areas with low moisture. However, in highly corrosive environments, like coastal regions or chemical processing plants, 304 fasteners may show signs of rust or pitting over time.

2. 316 Stainless Steel Fasteners

When superior corrosion resistance is needed, 316 stainless steel is the go-to choice. The addition of molybdenum in its composition significantly improves resistance to chlorides and saltwater exposure. This makes 316 stainless steel fasteners ideal for marine applications, outdoor construction, and industries dealing with harsh chemicals.

Compared to 304, 316 stainless steel fasteners can maintain strength and appearance much longer in corrosive environments, reducing maintenance costs and extending the service life of equipment and structures.

3. 410 Stainless Steel Fasteners

Grade 410 offers moderate corrosion resistance and high strength due to its martensitic structure. However, it’s less corrosion resistant than 304 or 316 and is more suitable for dry or mildly humid conditions where high mechanical strength is prioritized over corrosion resistance.

Choosing the Right Stainless Steel Fasteners for Your Application

Selecting the right stainless steel grade depends on the environment and performance requirements:

- Indoor or mild outdoor use → Choose 304 stainless steel fasteners for cost-effective corrosion resistance.

- Marine or chemical exposure → Opt for 316 stainless steel fasteners for the best protection in corrosive environments.

- High-strength, dry applications → Use 410 stainless steel fasteners where mechanical performance matters most.

By understanding how corrosion resistance varies among grades, you can make smarter choices that improve safety, durability, and long-term value.

FAQ: Stainless Steel Fasteners and Corrosion Resistance

1. Which stainless steel fastener is most corrosion resistant?

Among common grades, 316 stainless steel fasteners provide the highest corrosion resistance due to the addition of molybdenum, which enhances protection against salt, chemicals, and harsh weather conditions.

2. Is 304 stainless steel good for outdoor use?

Yes, 304 stainless steel performs well in most outdoor environments. However, in areas with high salt exposure or industrial pollution, 316 stainless steel is recommended for better long-term corrosion resistance.

3. Can stainless steel fasteners rust?

Stainless steel fasteners are corrosion resistant, not completely corrosion-proof. Under extreme corrosive environments, such as constant contact with seawater or strong chemicals, even stainless steel may develop surface discoloration or minor rust spots over time.

4. What is the difference between 304 and 316 stainless steel fasteners?

The main difference lies in chemical composition. 316 stainless steel contains molybdenum, giving it superior resistance to chlorides and acids compared to 304 stainless steel. This makes 316 ideal for marine or chemical applications.

5. Are stainless steel fasteners magnetic?

Most 304 and 316 stainless steel fasteners are non-magnetic in their annealed state. However, 410 stainless steel fasteners, being martensitic, are magnetic and stronger but less corrosion resistant.

Conclusion

Not all stainless steel fasteners are equally corrosion resistant. While 304 may be sufficient for many general uses, 316 stainless steel stands out as the best choice for severe corrosive environments. Choosing the right grade helps ensure that your fasteners remain durable and dependable — no matter the conditions.