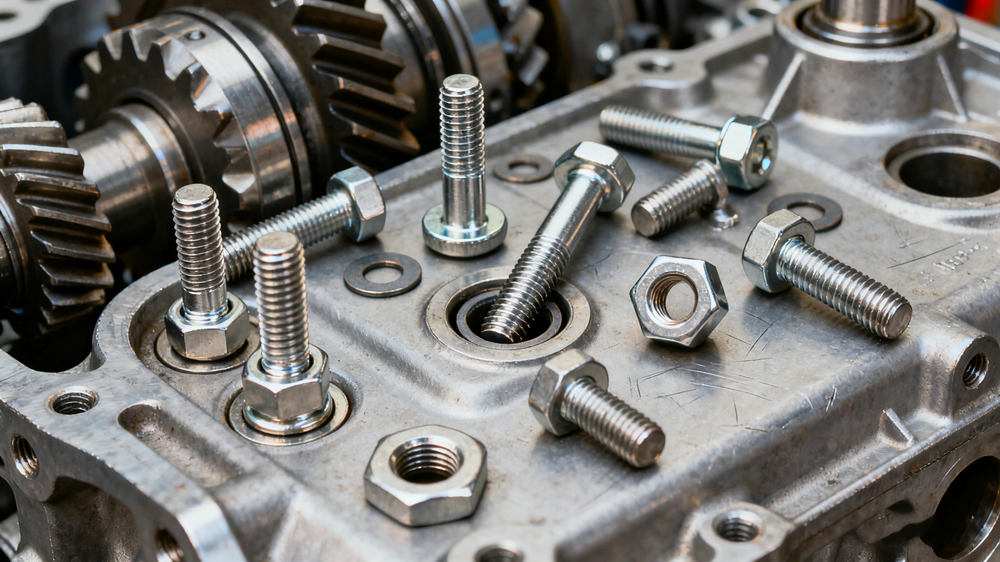

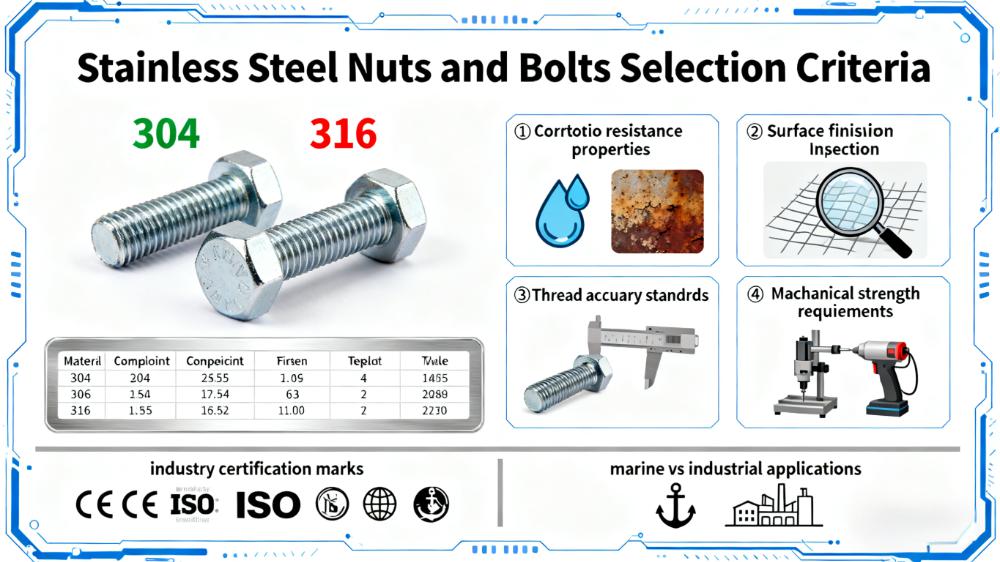

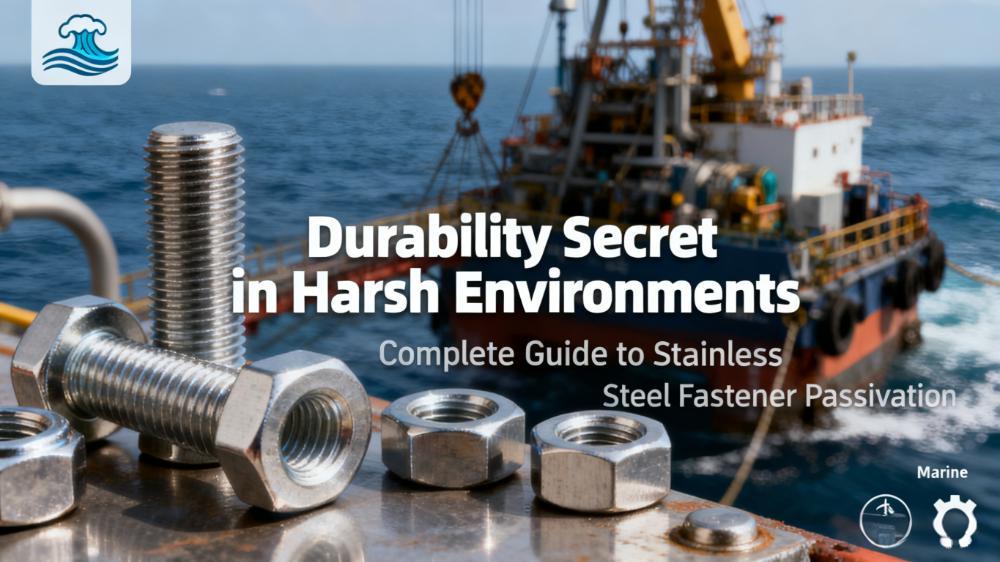

Industrial Applications of Stainless Steel Fasteners: Marine, Construction, and Automotive Focus

Stainless steel fasteners are among the most reliable and versatile components in modern engineering and manufacturing. Known for their strength, corrosion resistance, and durability, they play a crucial role in a wide range of industries.